The diamond smoothing tool represents a milestone in surface finishing technology and is particularly known for its ability to refine even harder workpieces (up to 65 HRC) at a microscopic level. The diamond smoothing tool utilizes the hardness of diamonds to machine workpieces with the highest precision. Through the use of diamonds, the diamond smoothing tool can produce surfaces with extremely low roughness and microroughness. This is particularly important in industries such as aerospace, medical technology, and precision manufacturing, where minimal imperfections are crucial. The hardness of diamonds not only ensures outstanding surface quality, but also improved durability and tool life. This leads to a cost-effective solution, as replacement intervals are extended and productivity is increased. The diamond smoothing tool represents an innovative solution in manufacturing technology that meets the highest demands for precision, durability, and surface quality. In industries where perfection is a must, the diamond smoothing tool sets the standard for excellent surface finishing.

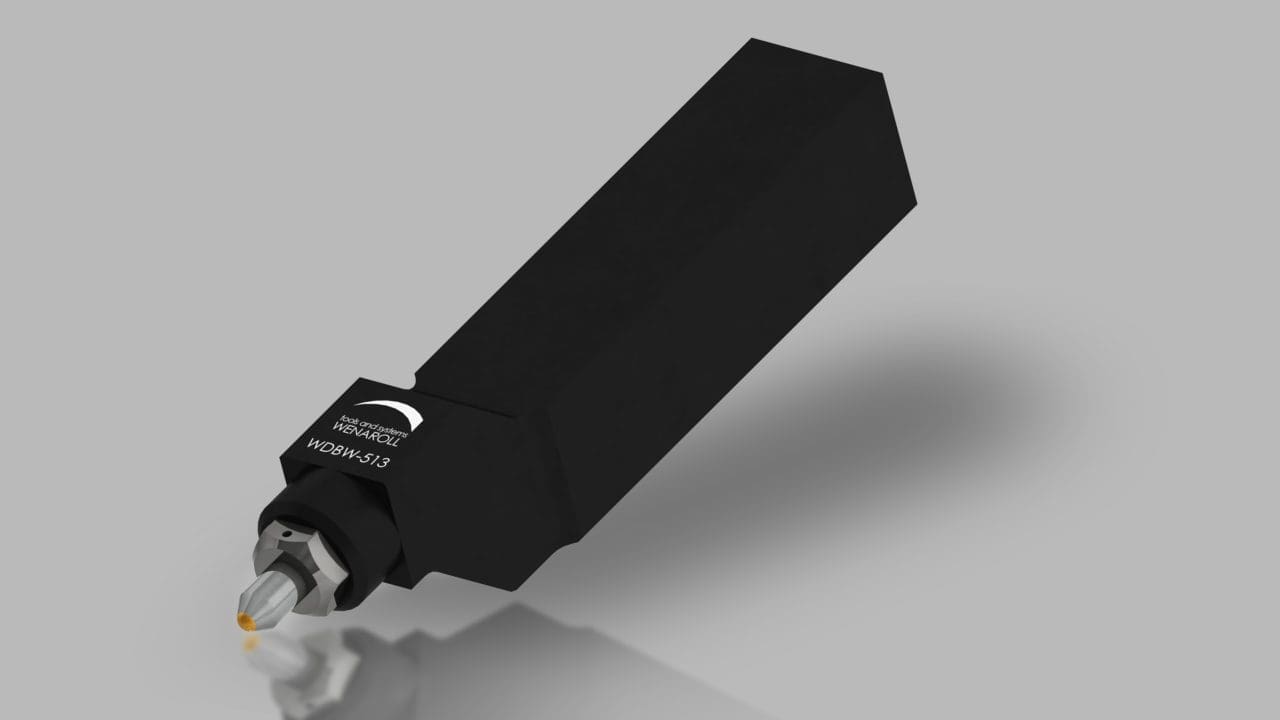

We offer various tool types for different application areas. The type WDB represents rigid tools where the head is not rotatable. Here you can choose between a clamping bar and an HSK tool holder. Special tool holders are also possible.

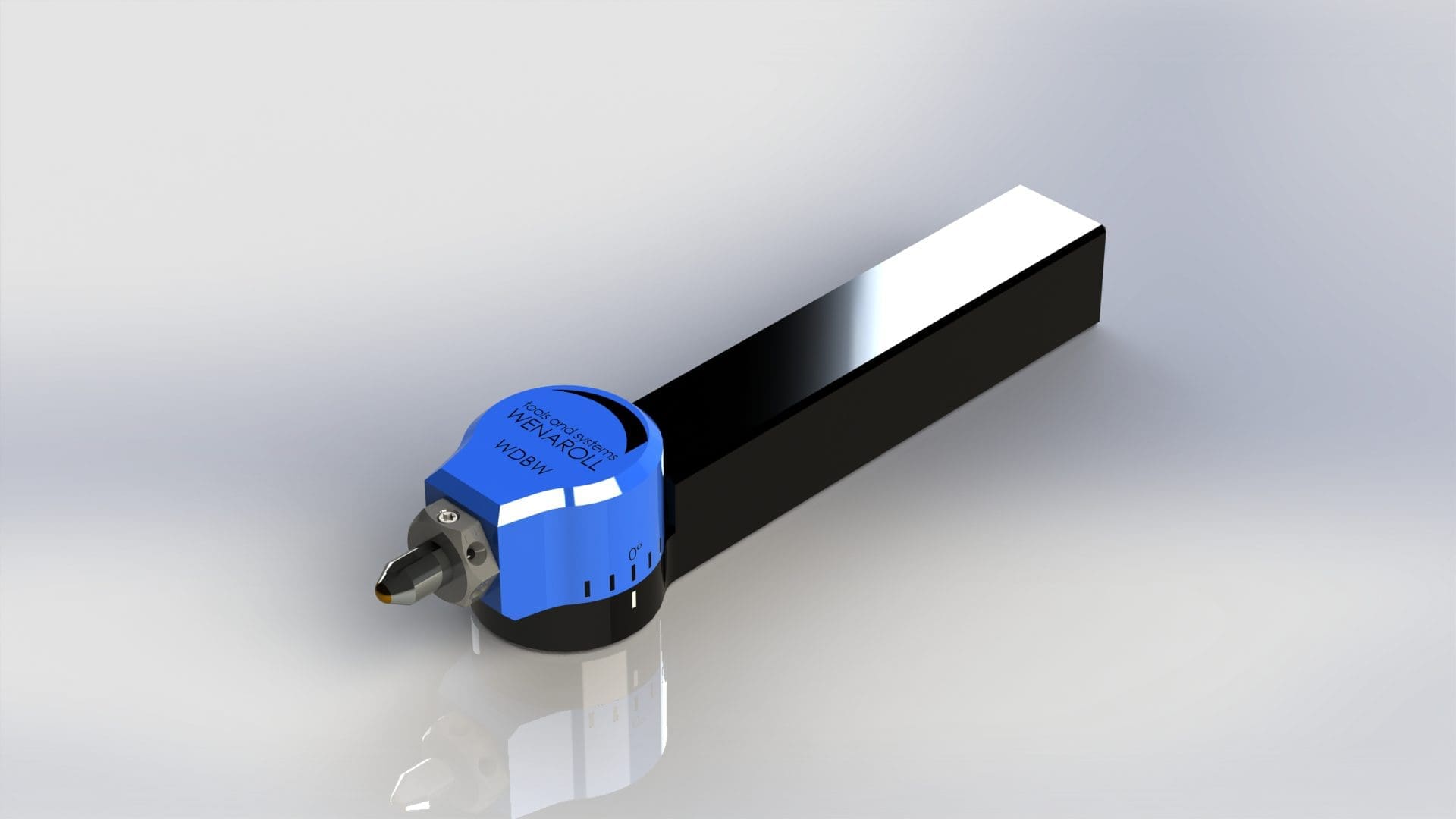

The WDBW type stands for an adjustable head. This expands the range of application. Here you can choose between a clamping bar and a cylindrical tool holder. Special holders are also possible.

Click on the diamond smoothing tools shown below to get more information.