Tapered Internal Surface Type WIK

Tapered Internal Surface Type WIK

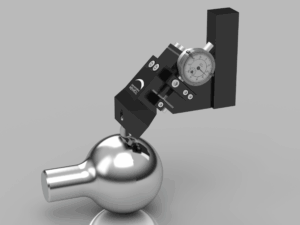

- Fast, reliable, and sustainable production of surfaces with a quality of Rz < 1 µm

- Creation of functional surfaces on all rotary machining machines

- Long service life of wear parts

- Non-cutting and virtually noiseless machining

- Enables quick replacement of wear parts

- Compatible with any cooling system and requires minimal cooling

- Quick adjustment of the burnishing tool

- Equipped with a spring-relieved retraction system

- High importance and a sustainable alternative for environmental protection

Description

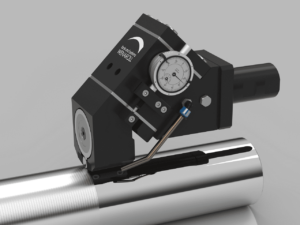

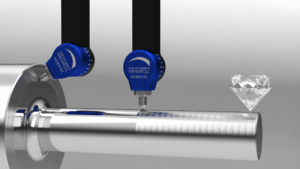

WENAROLL type WIK roller burnishing tools have been specially developed for machining internal taper surfaces. The tool body is equipped with a special spring system that allows individual pressure adjustment for each workpiece. The spring assembly is specially designed for each roller burnishing tool, so we can guarantee that excellent surface quality is achieved. At the same time, the spring assembly protects the tool and the machine from overloading. This ensures that identical forces are always applied to the workpiece, resulting in a precise and consistent force.

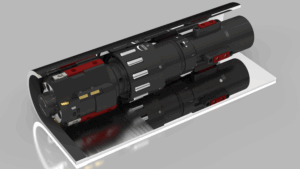

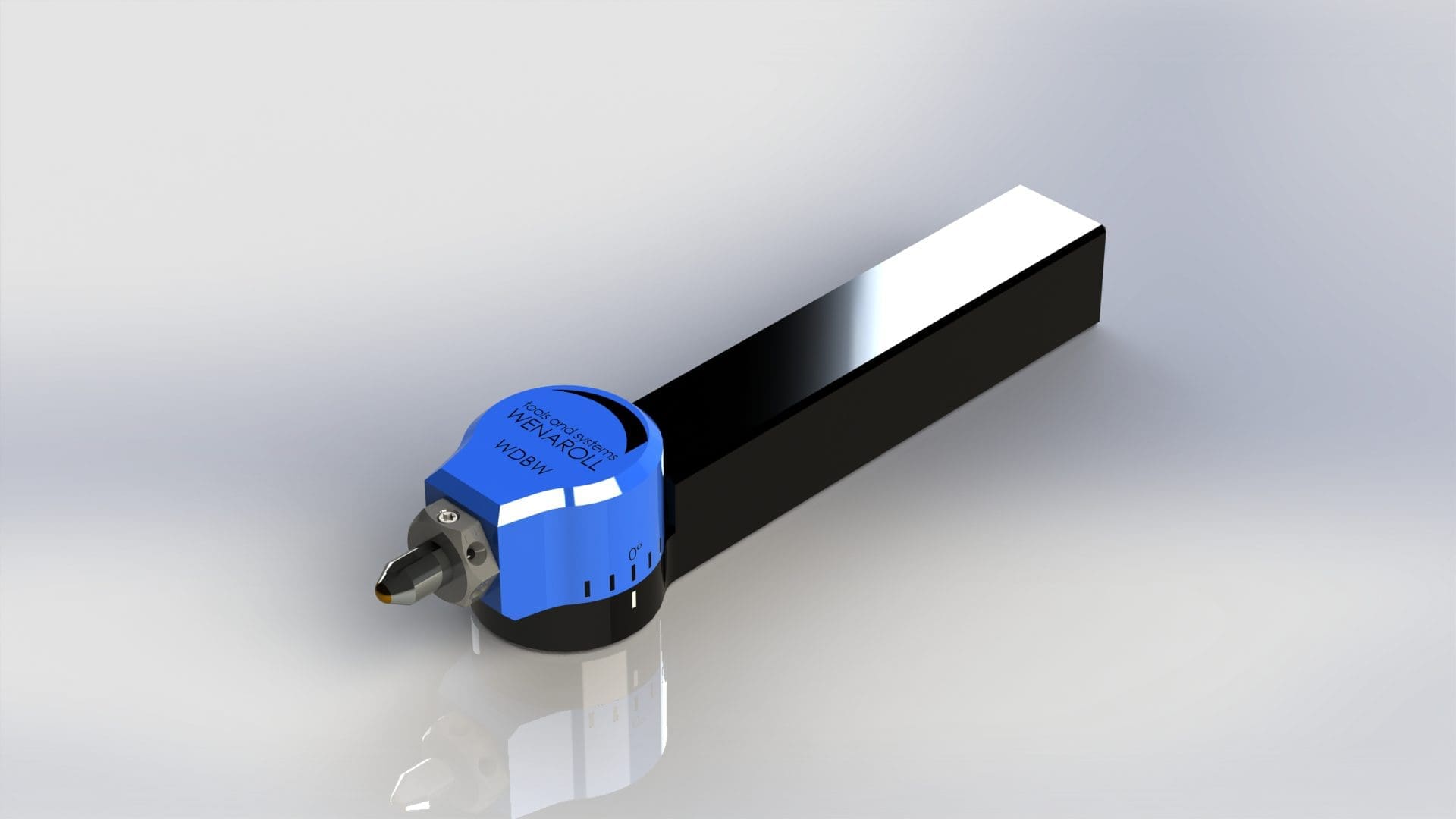

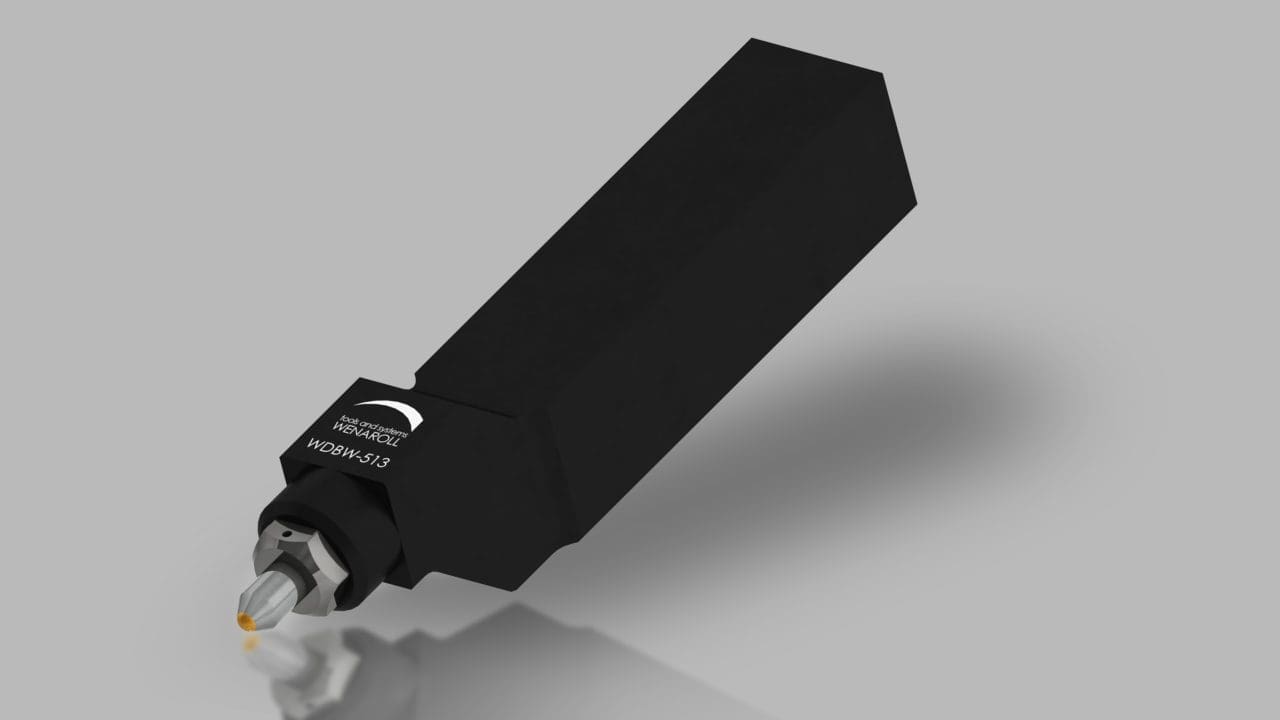

Tool structure

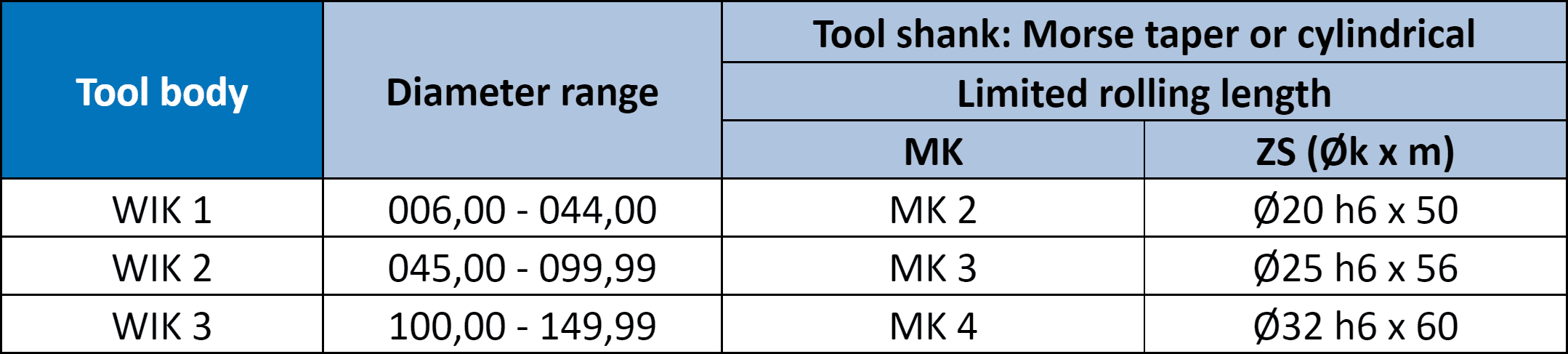

Wenaroll internal burnishing tools type WIK consist of a tool body and a burnishing head. The tool body has a mechanism for precise adjustment of the processing diameter of the roller burnishing tool. The cage, rollers and taper are wearing parts of the roller burnishing tool and can be replaced quickly and easily. The tool shank of the roller burnishing tool can be supplied cylindrical, as a Morse taper or in a special design according to customer requirements.

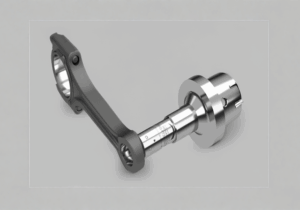

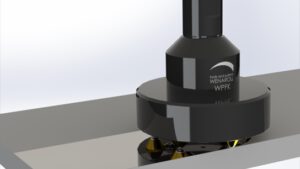

Machining

All metallic materials with a tensile strength of up to 1400 N/mm² and a maximum hardness of 45 HRC can be processed with our internal taper burnishing tool type WIK. Either the workpiece or the roller burnishing tool can rotate. The roller burnishing tools can be used on conventional CNC machines as well as on machining centers, lathes and milling machines.