External Taper Roller Burnishing Tool Type WAK

External Taper Roller Burnishing Tool Type WAK

- Can quickly and reliably produce surfaces with a quality of Rz < 1 µm

- Wear parts have a long service life

- Non-cutting and virtually noiseless machining

- Can be used on all rotary machining machines

- Requires minimal cooling and can be operated with any cooling system

- Enables quick replacement of wear parts

- Specifically adapted to your workpiece

Description

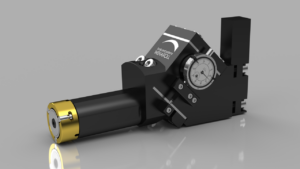

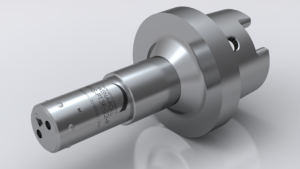

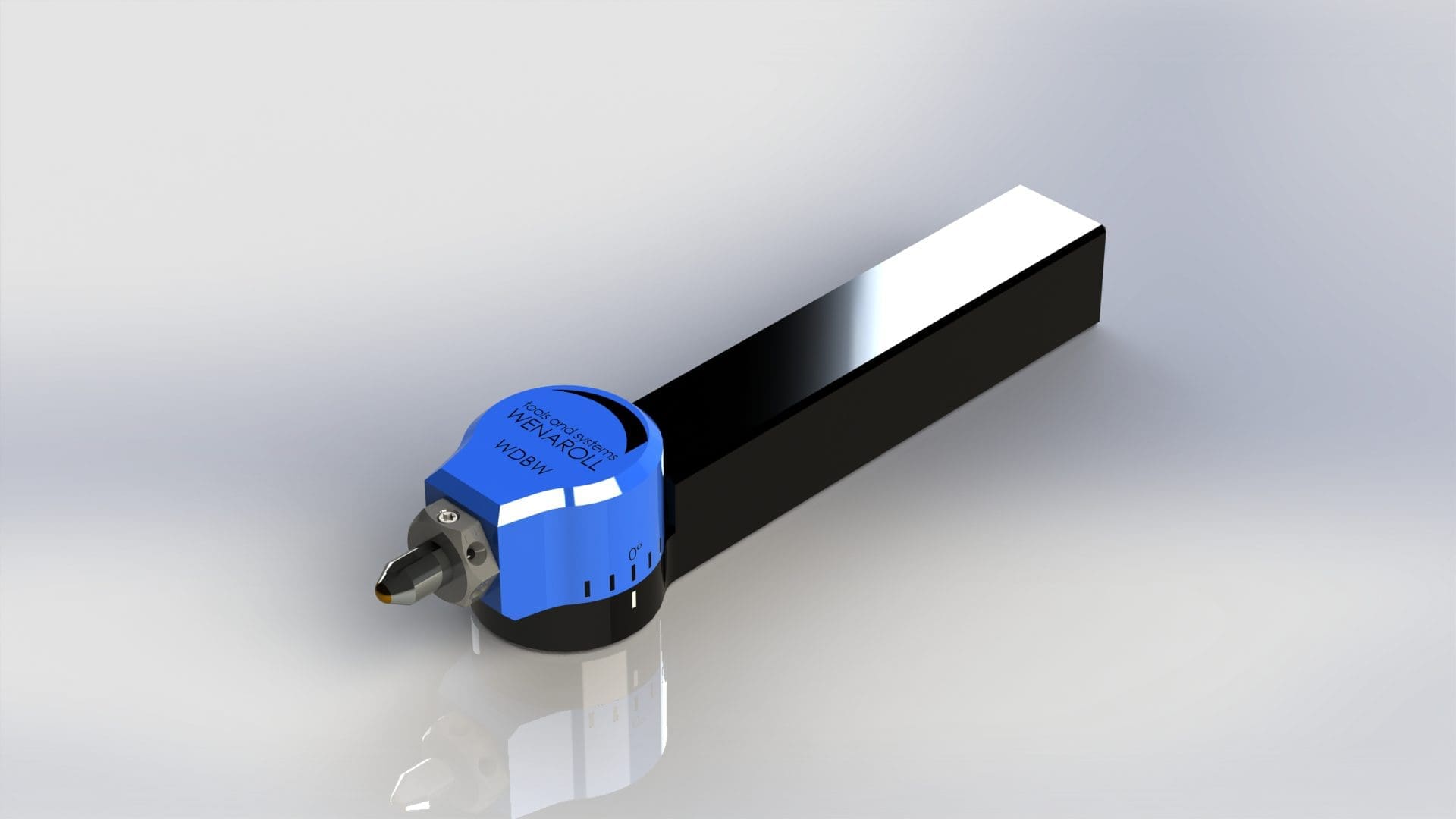

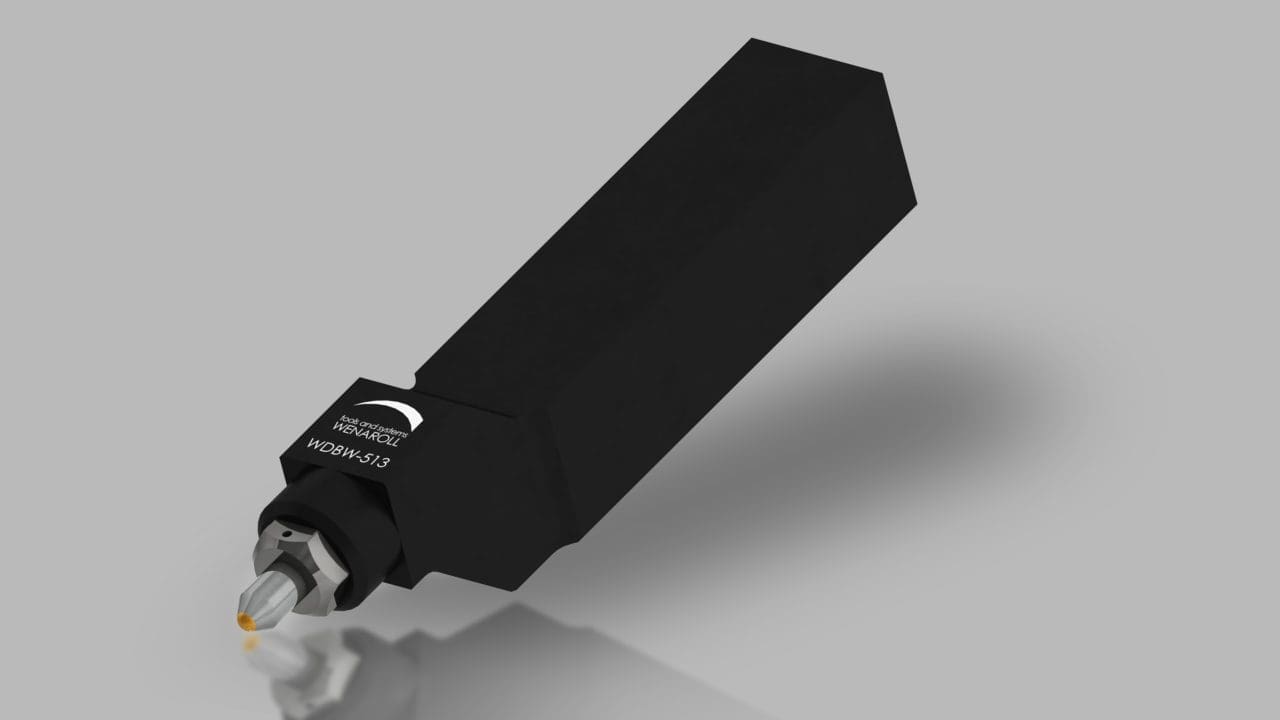

Our WAK type external taper roller burnishing tool is specifically designed for machining external tapered surfaces. The tool body is equipped with a special spring system that allows for individual pressure adjustment for each workpiece. The spring package is specifically determined for each roller burnishing tool, therefore we can guarantee that excellent surface quality is achieved. At the same time, the spring package protects the tool and the machine from overpressure. Thus, it is ensured that identical forces always act on the workpiece, achieving precise and consistent force.

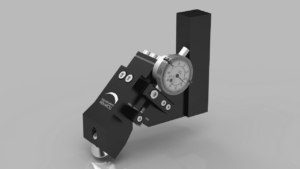

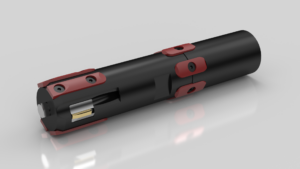

Tool structure

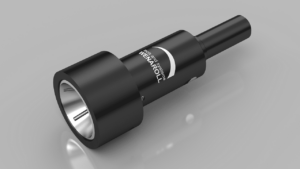

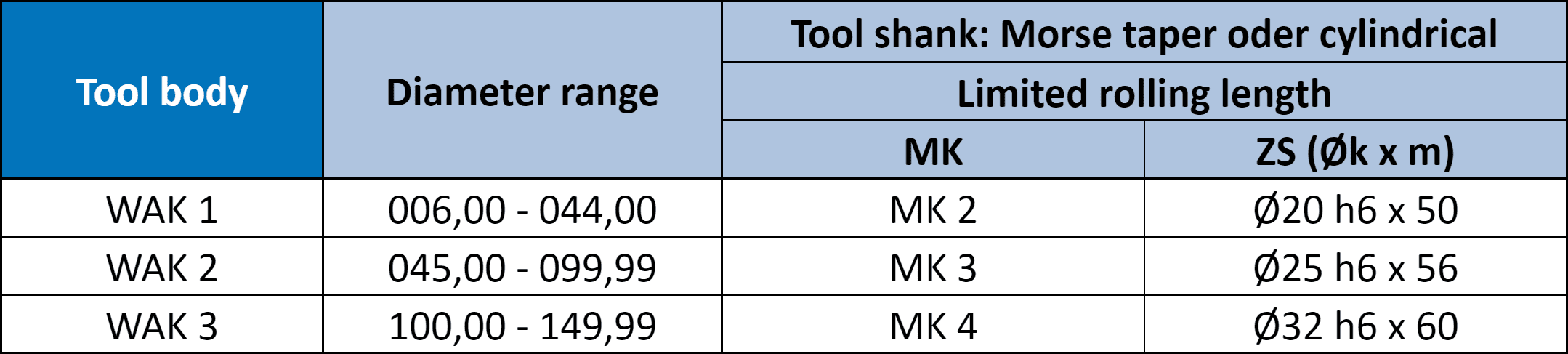

The WAK type external taper roller burnishing tool consists of a tool body with a roller burnishing head. The tool body includes an outer cage, equipped with a preloaded spring package and a shank for machine mounting. The tool shank can be supplied in cylindrical, Morse taper, or a special design. The arrangement of the spring package in the tool body is matched to the specified working conditions of the roller burnishing process. Cage, rollers, and cone are wear parts and can be easily replaced. Please note that the tools and spare parts of these tool types must be designed specifically for each application, and therefore no stock keeping is possible.

Machining

These tools cannot be adjusted. The roller burnishing process starts when the tool head, which has been specifically adapted to the workpiece contour, approaches/contacts the workpiece with a defined force. Either the tool or the workpiece must rotate during the machining process. These tools can be used on any machine where a rotating process takes place (lathes or milling machines, machining centers, special machines).