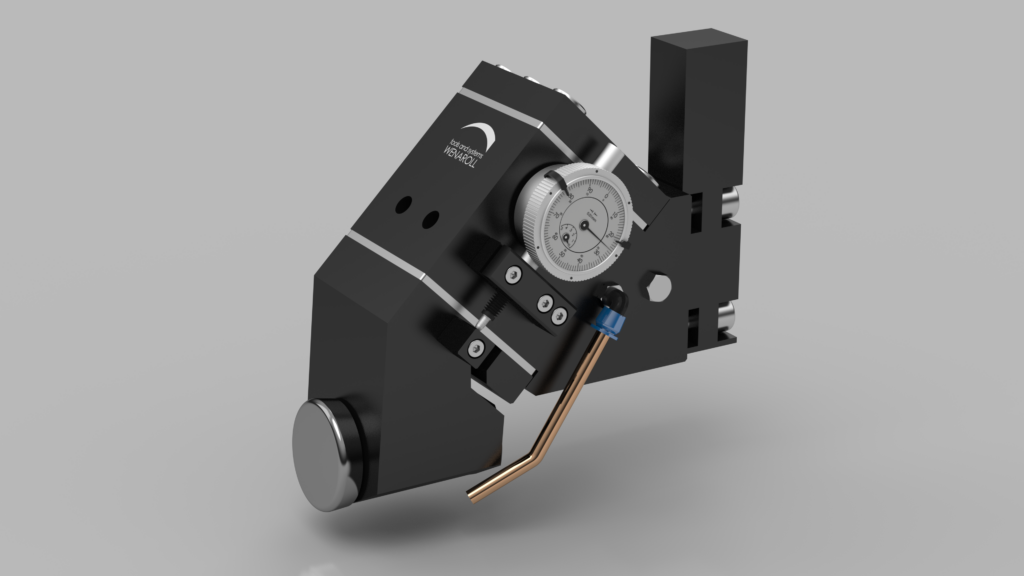

Contour Roller Burnishing Tool Type ERGH-45H

- Tools roller burnish transition radii, cylindrical, spherical, conical and flat surfaces, chamfers and contours

- Time saving due to short set-up time

- Application of residual compressive stress and work hardening

- Consistent and controlled work result by measuring the rolling force

- Enables quick replacement of wear parts

- Requires hardly any lubrication

- Rolling force quickly and continuously adjustable

Description

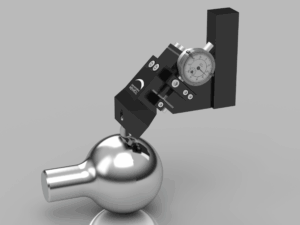

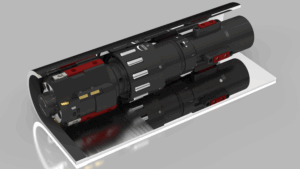

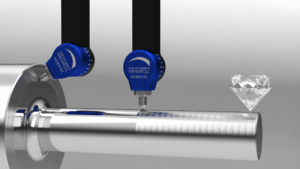

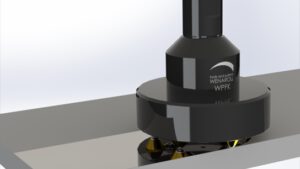

Our ERGH Contour Burnish tools enable the machining of cylindrical shafts, cylindrical bores, flat surfaces and spherical or conical parts. The ERGK version is particularly suitable for radii due to the inclined contour roller. The angle of the contour roller is either 45° or 90°, enabling radii to be completely machined.

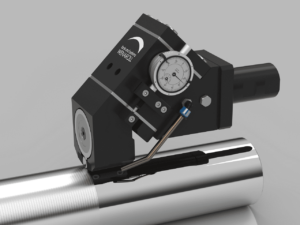

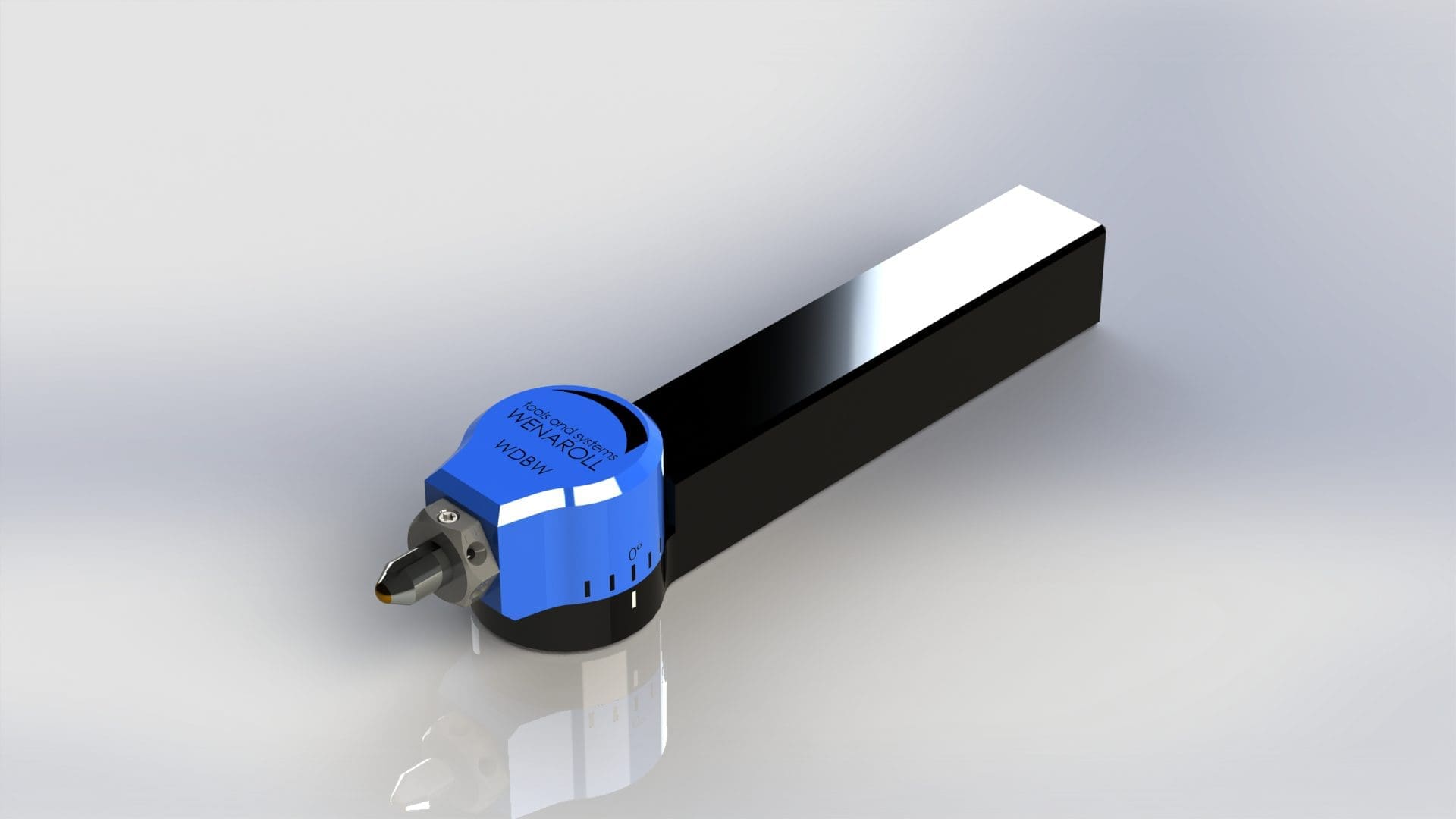

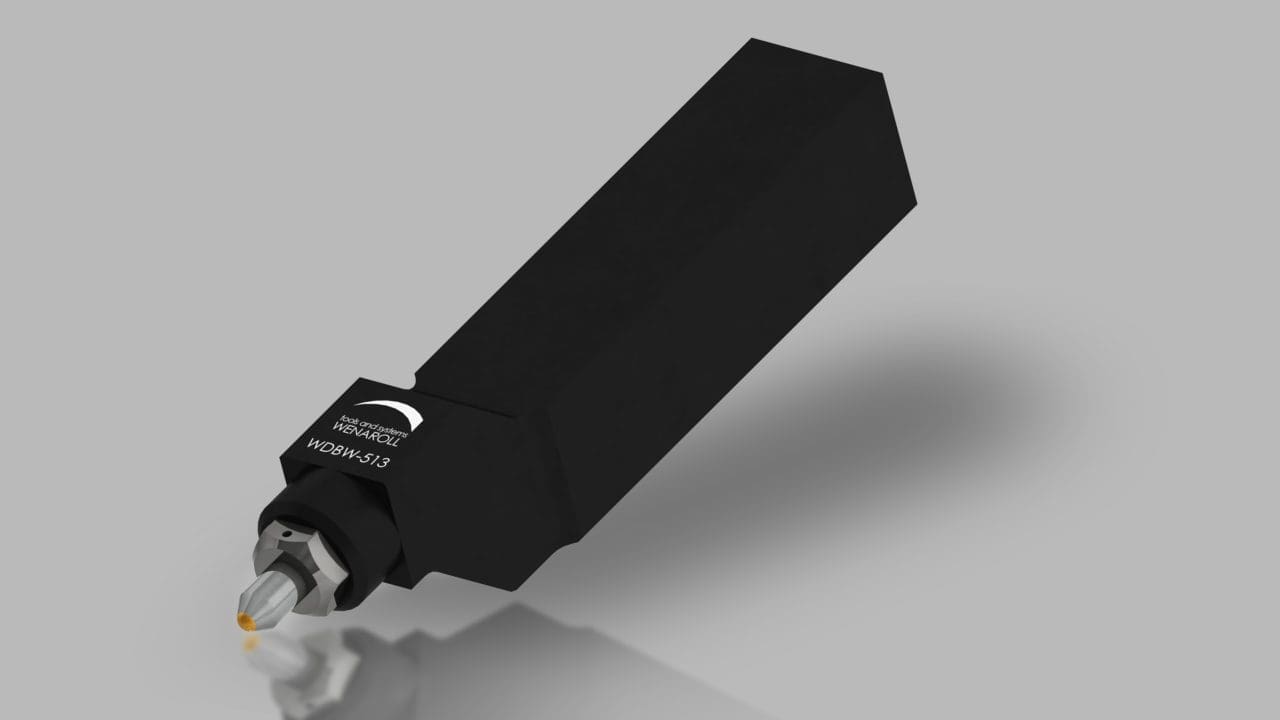

Tool structure

WENAROLL ERGH Contour Burnishing tools consist of a tool body with a removable roller holder and a holder that fits your machine. There is a dial gauge on the side of the tool which indicates the tool spring travel. Using the tables supplied by us, you can adjust the rolling force continuously and adapt it to your component.

Machining

This tool is suitable for machining materials with a maximum tensile strength of 1,400 N/mm² and a maximum hardness of 45 HRC. During machining, the workpiece rotates at the calculated speed and the tool traces the contour. The maximum peripheral speed of the workpiece is 300 m/min and the feed rate is 1 mm/rev, depending on the required surface quality. Only small amounts of lubricant are required during the process, and both emulsion and oil can be used. Either CNC machines or conventional turning machines with hydraulic copying devices can be used for machining. Machining in a single clamping operation. The rolling force can be increased or decreased by the tool infeed, which means that a wide range of materials can be processed