Cylinder tube machining

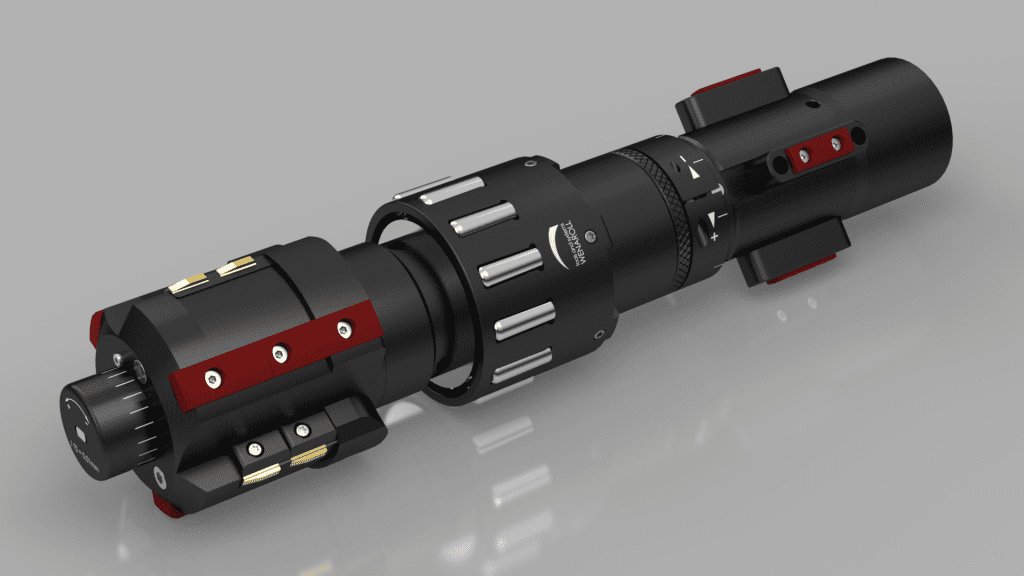

Cylinder tube machining places the highest demands on dimensional accuracy, shape accuracy and surface quality of the inner surfaces. As a specialist in surface finishing, Wenaroll offers highly productive tooling solutions that can replace the traditional honing process in many areas. In particular, the combined skivingand rolling technology enables the finishing of hydraulic cylinder tubes in a single operation – quickly, precisely and economically.

The inner surface of a cylinder tube is the main functional surface along which a piston with sealing elements will later slide. An optimal surface is important for the efficiency, tightness and service life of the entire hydraulic or pneumatic cylinder. The required surface must have minimal roughness and a high bearing ratio in order to minimise wear on the seals and ensure reliable lubrication.

Modern machining methods with Wenaroll tools:

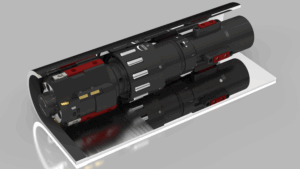

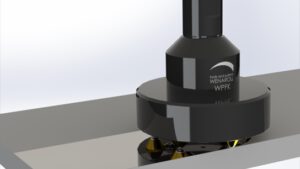

In place of time-consuming, multi-stage honing, combined skiving and forming machining has established itself as a superior alternative. Wenaroll specialises in tools that optimise this process:

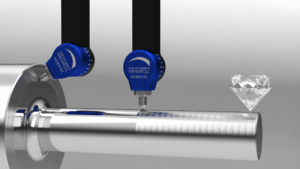

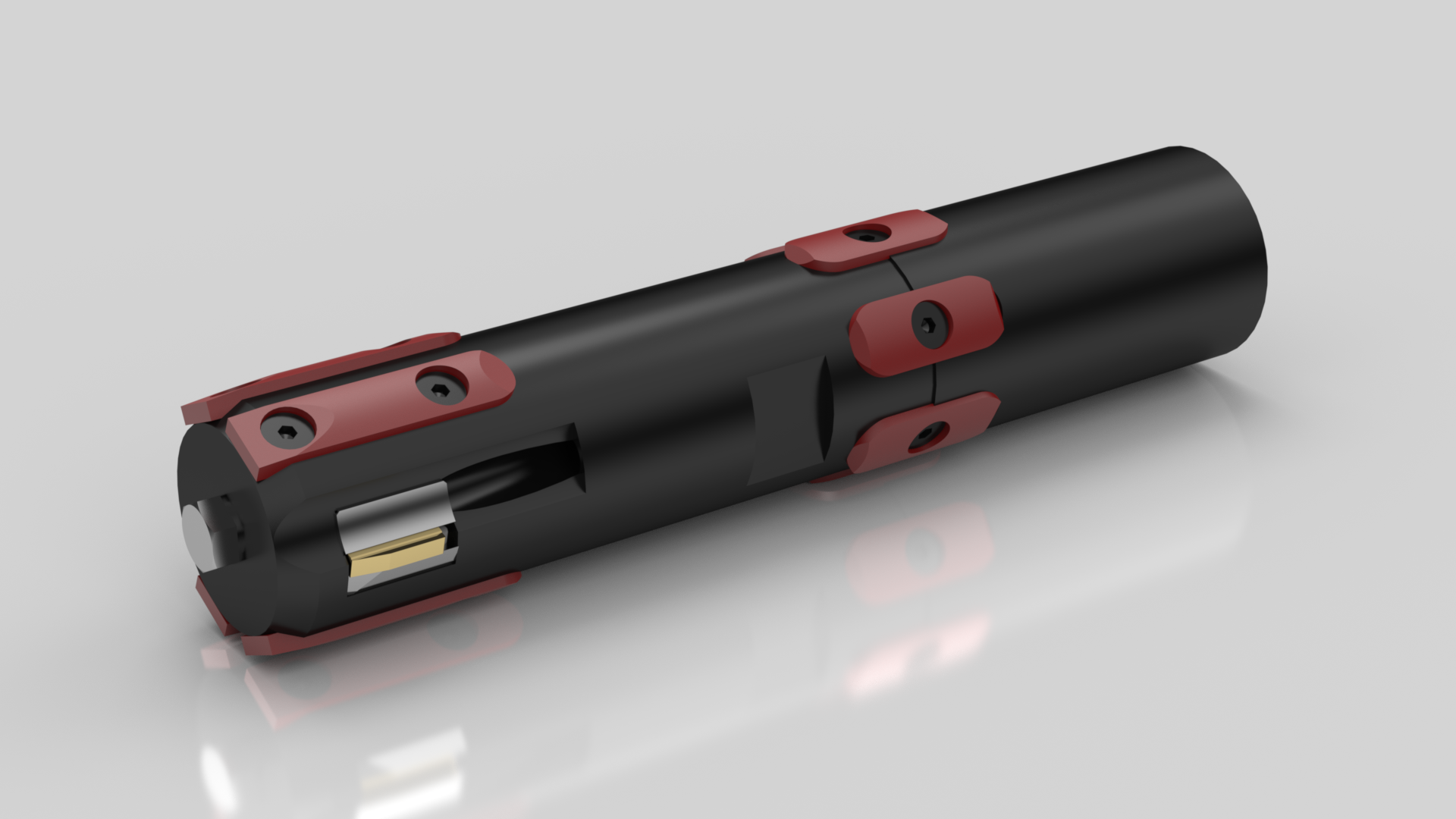

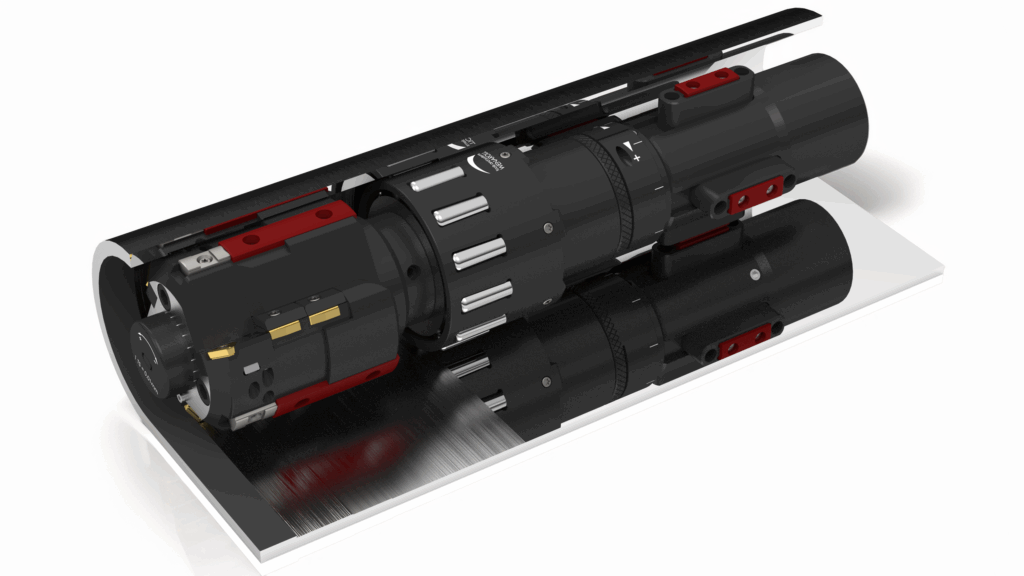

Skiving (chipping pre-processing): In the first step, the inside of the cylinder tube is skived to a precise intermediate dimension. A skiving tool with special cutting inserts removes material, creating a precise geometry and a defined surface as the basis for the next step.

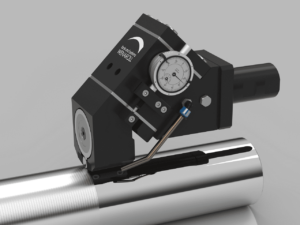

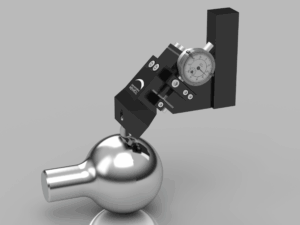

Roller Burnishing (forming finish): Aroller burnishing tool follows directly in the same operation. This tool plastically deforms the surface created by skiving. The surface roughness is leveled, and the surface layer is work-hardened. The result is an extremely smooth, hard, and wear-resistant running surface with excellent tribological properties (Rz < 1 µm).

The advantages of Wenaroll technology:

- Enormous time savings: The combination of skiving and roller-burnishing in a single tool and pass (f.e. with the Wenaroll type WPS) reduces the processing time by up to 90% compared to honing

- Excellent surface quality: Creates mirror-smooth, load-bearing surfaces that maximize the service life of cylinder seals.

- Increased process reliability: The process is cleaner than honing (no honing stones, no special oil) and delivers consistently repeatable results in size, shape and roughness.

- High economic efficiency: Shorter cycle times, longer tool life and the elimination of entire process steps lead to a significant reduction in manufacturing costs.

- Flexibility: Wenaroll offers tools for a wide range of diameters and lengths and enables the machining of both seamless (S355) and welded cylinder tubes.